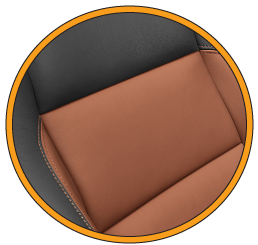

| INSERT | |

| COMBO | |

| BODY | |

| CENTER | |

| FACE |

|

|

|

|

|

|

|

|

|

|

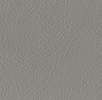

091 Dove Gray |

092 STONE |

093 SHALE |

094 DESERT |

095 BRONZE |

096 DK STONE |

097 KHAKI |

098 PARCHMENT |

099 LT BRONZE |

100 SAND |

|

|

|

|

|

|

|

|

|

|

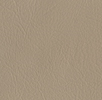

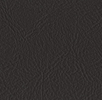

087 ASH |

073 BEIGE |

001 BLACK |

003 BLUE |

075 BRIGHT RED |

113 BROWN |

006 BUCKSKIN |

081 BURGUNDY |

085 CAFE |

119 CAMEL |

|

|

|

|

|

|

|

|

|

|

007 CORDOVEN |

084 CUSTARD |

005 DARK BLUE |

120 DK BROWN |

79 DK CHARCOAL |

115 DOE SKIN |

088 EARTH |

083 ECRU |

090 FAWN |

086 FOG |

|

|

|

|

|

|

|

|

|

|

008 GRAPHITE |

112 GRAY |

080 ICE |

125 IVORY |

004 JADE |

072 LT GRAY |

139 MAROON |

074 MED. RED |

076 MIST |

117 NICKLE |

|

|

|

|

|

|

|

|

|

|

118 OLIVE |

140 OPAL |

122 QUICKSILVER |

600 RED |

142 SADDLE |

009 SAND STONE |

116 SILVER LEAF |

089 SLATE |

141 SNOW |

121 TAN |

|

|

|

|||||||

517 TAUPE |

083 TITANIUM |

077 WILLOW |

Most vehicles made in the last 15 years have quality paint and durable plastic interior trim. The seating surfaces are another story however; cloth can wear out, before your car or truck loses its comfort, visual appeal and resale value, upgrade the interior with new leather upholstery from Dye Guy Inc..

Dye Guy Inc. has more than 2,500 leather interior package options for popular domestic and import applications. These premium interiors feature luxurious automotive-grade leather, which is through-dyed to practically eliminate the white cracking associated with lesser leathers. Tru-Tone color-matching technology replicates the factory look. Or choose from multile color options.

Dye Guy Inc. colors and styles including two-tone, perforation, suede, and carbon fiber. All hides are hand-selected for grain and softness by professional inspectors prior to being cut by state-of-the-art machinery, and meticulously hand-sewn by skilled craftsmen using the best in sewing technology. Other options include contrasting insert and stitch colors, welt cord piping and a wide variety of embroidered and heat-embossed logos. No long waits or warranty hassles either ; Dye Guy inc. leather interiors are manufactured and shipped in mere days and are backed by an amazing 3-year / 36,000 mile limited warranty.

ABOUT LEATHER

Leather is a natural product that reacts differently to soil and light. Some types of leather have greater resistance because of the techniques used in finishing the hides. The natural surface of

leather is like a landscape, with varying textures and shadowy furrows. These distinctive features are unique to genuine leather, a product that has been raised rather than engineered. No two

hides will be exactly alike, as with all things in nature.

Leather is the strongest upholstery material traditionally used for furniture and has been proven to outlast fabric at least four to one. While all leather is inherently durable and strong,

there are significant differences between leathers. Top grain leather is the strong supple top layer of the hide. These hides have been processed to retain the leathers' natural ability to

constantly adjust to its environment. It absorbs moisture and regulates its surface temperature so that it is warm and comfortable in the winter and cool in the summer. Leather, a product

of nature, has its own life history recorded as grain, wrinkles, scratches and scars acquired from life on the range.

Understanding Leather's Natural Markings

Even the best leather has natural markings, which are analogous to fingerprints. They distinguish genuine leather from man-made materials. Some marks which can appear on the surface of

leather are healed scratches, barbed wire marks, wrinkles and insect bites. Any of these markings may be present on your furniture and is your assurance that you have a true top grain leather.

Leather is a natural product; grain pattern and color may vary from hide to hide and within the hide.

Shade and Tone Variation

Leather is unique as an upholstery covering. Surface features testify to the authenticity of natural leather. Variation across a hide, density of grain, creases and folds are distinctive

characteristics, much like the grain of a fine piece of wood. Leather is not like a bolt of cloth. On a sofa, five hides may be utilized which will blend and complement, but will never be identical.

Like any natural product, grain pattern and color may vary from hide to hide and within each individual hide. In the dying process, no pigments are used, so each hide absorbs "color" based on its

individual cell structure. Each area of the hide will absorb dye in varying amounts, and thus be darker or lighter than other areas; much like wood varies in color when stained. This explains

why an arm of a leather sofa may have a different shade than the cushions or the back of the sofa. They were simply cut from different parts of the same hide.

Healed Scars

Healed scratches are reflective of the steer's lifelong encounters. These healed scratch marks are evidence of this cow's unsheltered life. These form as a result of barbed wire scratches,

disease and infestation or by horns of other cattle. The new healed skin is as strong as the remainder of the hide. It is normal to use scars and areas of rough grain on the outside backs and

arms. Markings on your leather furniture are natural, and in no way affect the strength or wear ability of the leather. These unique characteristics are your assurance of genuine leather.

Wrinkles

Neck and shoulder creases appear as elongated furrows. Wrinkles naturally occur in a hide as a result of the neck stretching and contracting. Skin located on the neck of a steer is full and

loose. This enables the steer to have the flexibility it needs to move its head while grazing. Wrinkles, naturally occur in the hide.

Variation in Grain

Variations in grain pattern occurs during the life of a steer. The grain is relatively tight across the backbone while it may be very loose in the belly and flank areas. The looser areas consequently

have more stretch. Graining, like human fingerprints, is unique to each individual hide.

Stretch Marks

Stretch marks appear in cowhides for the same reasons they do in humans. The process of calving requires the stretching of the skin to accommodate the new calf. Nothing could be more

natural. Stretch marks are used in leather furniture.

Veins

Growth marks and veins are an indication of the age of the animal and in that respect are similar to the graining on a piece of timber. They range from often quite pronounced marks in the

neck area to subtle bands across the hide perpendicular to the backbone. Again, these are quite natural and are used in furniture.

LEATHER Terms Glossary

Aniline:

Leather that is colored all the way through with a transparent dye. The effect is applied by immersing the leather in a dye bath. Because the finish is transparent and shows the natural

markings of the leather, only the best quality hides can be used.

Antiqued:

Leather that is dyed with one color over another (usually darker over lighter) so as to create rich highlights and an artificial aged appearance. It is also called distressed leather.

Buffed Leather:

Leather from which the top surface has been removed by abrasion. Often known as suede or nubuck.

Corrected Grain:

Leather that has been buffed to remove blemishes, then covered with a new, artificial grain created using pigments and other finishes.

Crocking:

Removing the crock, or excess coloring, that rubs off of a newly-dyed hide

Crust:

Leather which has been tanned (treated to become nonperishable) but not colored or otherwise finished.

Distressed:

Another term for antiqued leather.

Drum Dying:

The process of coloring leather by tumbling it in a rotating drum immersed in dye. This is a very effective method allowing maximum dye penetration.

Embossed Leather:

Leather that has been "stamped" with a design or artificial texture under very high pressure. It is used, for example, to create imitation alligator hide.

Finish:

Any enhancing effect applied to leather after it has been tanned. Examples are dyeing, embossing, buffing, antiquing, waxing, waterproofing, and so on.

Full Grain Leather:

Leather which has not been altered beyond hair removal. Full grain leather is the most genuine type of leather, as it retains all of the original texture and markings of the original hide.

Glazed Leather:

Aniline-dyed leather which has been polished to a high luster by passing through glass or steel rollers under great pressure.

Glove Leather:

Lambskin or other very soft leather typically used for gloves.

Grain:

A word used to describe the natural characteristics of an unprocessed hide, such as its pores, wrinkles, markings, and texture.

Hand:

A word used to describe the feel (i.e. softness or fullness) of leather, typically upholstery leather.

Nap:

Describes the soft, "fuzzy" effect achieved in leather by buffing or brushing.

Natural Grain:

Leather that displays its original grain.

Nuback Leather:

Also called Chaps, Distressed Unfinished, Naked, Bomber or Suede leathers. A leather whose surface has been buffed and brushed to create a soft, velvety effect. Differs from suede in

that while suede is created from the flesh (inner) side of a hide, nubuck is created using the grain (outer) side, giving it added strength and durability. You chose this leather because of

its natural beauty, soft hand and luxurious feel. Through years of experience, we have developed unique ways to maintain and protect these naturally tanned leathers. The lack of a coated

finish requires special attention.

Oil Tanned:

Leather that is tanned using oils to create a very soft, pliable finish.

Patina:

The aura or luster that develops in a quality piece of leather with age.

Perforated:

Leather in which a pattern of small holes is stamped using a die.

Pigmented Leather:

Leather that has been coated with a flat surface color on top of or instead of the usual dye finish. Leather is usually pigmented to

add durability and hide natural blemishes.

Plating:

The process of pressing leather under a heated plate. Often used in upholstery leather to mask imperfections.

Pull-up:

Describes the behavior of leather that has been treated with oils, waxes, and dyes in such a way that when the leather is pulled or

stretched (i.e. on upholstery), the finish becomes lighter in the stretched areas. It is considered a mark of high quality.

Re-tan:

A second finish added over an underlying tannage.

Savauge:

A coloring effect created by blending two similar dyes to create a mottled or marbled appearance.

Semi-Aniline:

Aniline leather to which a matching pigment layer is added to even out the color and add protection.

Side Leather:

Leather made from one half, or "side", of a full hide. Typically refers to leather whose top grain (outermost layer) has been left intact.

Split Leather:

Leather made from the lower (inner or flesh side) layers of a hide that have been split away from the upper, or grain, layers. Split leather

is more fragile than side leather or full-grain leather, and is typically used in the form of suede.

Suede:

Split leather that has been buffed and brushed to create a fuzzy surface feel.

Top Grain:

Leather whose top (outermost) layers have been left intact, in contrast to split leather.

Two-tone:

An effect created by applying layers of similar or contrasting dyes to a piece of leather in order to create a mottled or aged appearance.

Antiqued and Savage leathers are examples of two-tone leathers.

Upholstery Leather:

Leather created from a whole hide and intended for use in furniture, automobiles, airplanes, and other upholstery applications.

Vegetable Tanning:

A method of hide tanning which utilizes materials from organic materials such as bark instead of the traditional chemicals. Vegetable tanned leather has

greater body and firmness than traditionally-tanned leather.

Weight:

A term which describes the heaviness or thickness of leather. This is typically given in ounces per square foot or millimeters (thickness).

Whole Hide:

Refers to leather created using a full hide, as opposed to a side, and typically intended for use as upholstery leather.

History of LEATHER

Primitive people who lived during the Ice Age some 500,000 years ago, were likely the first to use the skins of animals to protect their bodies from the elements. Just as leather today is

a byproduct, our ancient ancestor's hunted animals primarily for food, but once they had eaten the meat, they would clean the skin by scraping off the flesh and then sling it over their

shoulders as a crude form of a coat. They also made footwear to protect their bare feet from rocks and thorns by taking smaller pieces of animal skin made to fit loosely over the foot

and tied at the ankle with thin strips of skin or even vines.

The main problem that primitive man encountered was that after a relatively short time the skins decayed and rotted away. With his limited knowledge and experience, primitive man had no

idea how to preserve these hides. As centuries passed it was noticed that several things could slow down the decay of leather. If the skins were stretched out and allowed to dry in the sun,

it made them stiff and hard but they lasted much longer. Various oily substances were then rubbed into the skins to soften them. As time passed, it was eventually discovered that the bark

of certain trees contained "tannin" or tannic acid which could be used to convert raw skins into what we recognize today as leather. It is quite hard to substantiate chronologically at

exactly what time this tanning method materialized, but the famous "Iceman" dating from at least 5,000 BC discovered in the Italian Alps several years ago, was clothed in very durable leather.

Somewhat later, techniques used by the American Indian are very similar to those used in this early period. These Indians took the ashes from their campfires, put water on them and soaked

the skins in this solution. In a few weeks the hair and bits of flesh came off, leaving only the raw hide. This tanning method, which used a solution of hemlock and oak bark, took about three

months to complete after which the leather was worked by hand to make the hide soft and pliable.

The Making Of Leather Goods

The tanning of leather was used by mankind in numerous geographical areas throughout the early periods of human civilization. As certain leather characteristics began to emerge, men realized

leather could be used for many purposes besides footwear and clothing. The uses and importance of leather increased greatly. For example, it was discovered that water would keep fresh and

cool in a leather bag. It was also found suitable for such other items as tents, beds, rugs, carpet, armor and harnesses. Ancient Egypt, one of the most developed civilizations in this early

period, valued leather was as an important item of trade. The Egyptians made leather sandals, belts, bags, shields, harness, cushions and chair seats from tanned skins. Many of these items

are in fact still made from leather today.

Similarly, the Greeks and Romans used leather to make many different styles of sandals, boots and shoes. When the Roman legions marched in conquest across Europe, they were well attired

in leather armor and leather capes. In fact, right up until the early 18th century, the shield carried by the ordinary soldier was more likely to be made of leather than metal.

The ancient Greeks refer to eight basic guilds of artisans, which included both shoemakers and tanners. Although tanning was originally a cottage trade, the Greeks had full-time professional

tanners who were at first employed in leather processing establishments and became independent some time later. The barks of conifers and alder were used as tannin sources and so were

the peel of the pomegranate, sumac leaves, walnut, cups of acorns as well as an Egyptian heritage - mimosa bark. The Greeks were also familiar with alum tanning and it appears they knew

something about tanning with fish oil. The types of leathers used were as diversified as the end users. Homer refers to the use of cowhide, goat and weasel leather by the Greeks.

The edict issued by the Roman emperor Diocletian which fixed ceiling prices for all kinds of goods and services included skins and leather prepared from goats, sheep, lambs, hyenas, deer,

wild sheep, wolves, martens, beaver, bears, jackals, seals, leopards and lions. Under the edict, cowhide was even classified according to groups and qualities. A complete tannery in the

famous ash-preserved ruins of Pompeii was unearthed in 1873.

As we move into the middle Ages, leather continued to increase in popularity. By far the cleverest craftsmen with leather in medieval times were the Arabs. The Moors developed remarkable

skill primarily in the preparation of beautiful goatskin still known as morocco leather after the country of its origin. In fact the description 'genuine morocco' is still very highly regarded

today, particularly in the manufacture of small leather goods.

In Medieval England, most industries were carried out by master craftsmen aided by apprentices under the supervision of the appropriate Craft Guilds. The leather trade was represented by

a large number of guilds including Cordwainers, Couriers, Fletchers, Girdlers, Glovers, Homers (Bottle makers), Leather Sellers, Loriners, Saddlers, Skinners, Pursers, Tanners and Harness-makers

as well as others. All kinds of containers were made from leather, such as sword cases and dagger sheaths, box coverings and water bottles, many of them beautifully decorated by punching and

incising. Leather was also a favorite medium for decorative art. Leather was used to cover books. In those days, when the horse was the principal means of transport, saddler and harness

making were important uses of leather.

Until the later part of the 19th century, there were relatively few changes in the methods used to produce leather. In fact, the process had changed very little in over 200 years. However,

the industrial revolution did not bypass tanning - one of the oldest and most basic forms of manufacturing. Science was quickly introduced to the art and craft of leather making. A wider

range of dyestuffs, synthetic tanning agents and oils were introduced. Together with precision machinery, these changes and continued innovations to the present day have combined to

make tanning into a viable, modern manufacturing industry.

LEATHER types:

The leather industry has gone through many changes. Steps have been taken to form different looks and feel to please a wide variety of customer wants and needs.

Determining the type of leather, how that leather was finished and the proper method to clean, maintain and protect these various leathers requires knowledge and experience. Often

the seller or the seller's representative does not know the proper method of leather care needed for a particular leather type purchased.

Leather is tanned, and or finished in may different ways. Below is some detailed information and the three main categories that leather is referred to today.

Finished, Pigmented, Semi Aniline, Aniline Plus & Everyday Leathers:

These leathers have combined the best aspects of a natural product (leather) and have utilized tannery technology to create a product that is more uniform in appearance and color

(due to the applications of pigments to the surface). It then has a finish applied to the surface that makes the leather more resistant to the effects of heavy use. The pigments

and finish applied to the leather do affect the softness and hand somewhat. As more pigment or finish is applied, the softness of the leather lessens. What determines the amount

of pigment and finish needed is: 1. The color of the leather, 2. The selection of the leather, 3. The desired level of resistance the finish needs. Protected leathers are by far the most

popular and common types of leather sold on furnishings. You can prevent peeling and finish decay by having these leathers cleaned, conditioned and re protected annually.

Aniline Leathers, also known as Natural, Unprotected, Pure or Naked Leathers:

These leathers are colored with transparent dye stuff. This means that you are able to see the actual surface grain and markings. It is as if you are looking through a colored lens.

These leathers have very little or no protective treatments applied to them. The most common thing to do is to spray a wax finish on the surface that gives short term water repellence.

The actual way that the leather is made varies from tannery to tannery.

Nubuck leathers, also known as Chaps, Distressed, Buckskin, bomber or Suede leathers:

These leathers are actually aniline leathers on which the surface has been brushed, and have created a texture similar to velvet on leather. Many people confuse these with Suede

leather. Suede is the flesh side of a piece of leather, and nubuck is an "effect" that is done to the grain side, making it incredibly soft. The brushing also makes the leather even more

absorbent than aniline leathers. This makes these two leathers sometimes difficult to distinguish from each other. The most difficult to identify are the ones which are in the distressed

leathers category or which have waxed finishes applied to them.

SERVICE AREAS FOR DYE GUY INC. AUTOMOTIVE RESTORATION SERVICE

HOUSTON - PEARLAND - CYPRESS - SPRING - KATY - SUGARLAND - BELLAIRE

WEST UNIVERSITY PLACE -

SOUTH HOUSTON - MISSOURI CITY - DEER PARK

MISSION BEND - STAFFORD -

PASADENA - THE WOODLANDS - RICHMOND- ROSENBERG

.............................................................................